30-500TPD Continuous and automatic vegetable oil refining machine/corn oil refining machine

Basic Info

Model No.: HT-VSOM

Product Description

oil refining production line process indicators:

1.1.0 refined sunflower oil quality indicators

1.1.1 Lovibond slot (25.4mm) yellow red ≤ 3.0 ≤ 35

1.1.2 smell, taste: sunflower oil has inherent smell and taste, no smell

1.1.3 moisture and volatile matter (%) ≤ 0.10

1.1.4 insoluble impurities (%) ≤ 0.05

1.1.5 peroxide value (mmol / kg) ≤ 7.5

1.1.6 Heating test (280 ℃) no precipitation, Lovibond color: yellow value unchanged, increasing red value is less than 0.4

1.1.7 the amount of soap-containing (%) ≤ 0.03

1.1.8 residual solvent oil extraction / crushing oil: ≤ 50 / not detected

1.1.9 Acidity (KOH meter) (mg / g) ≤ 1.0

Refined process diagram:

Phosphoric acid, lye, water Vacuum

↓ ↓ ↓

press crude oil→ dephosphorizing , degumming, washing → drying, bleaching →filter → deodorized→ finished oil

↓ ↓ ↓

Soapstock clay waste clay

Process Description:

Degumming,alkali refining and water washing section

Remove impurities from crude pressing oil with filter,use oil pump to convey it into refining tank in refining workshop, add phosphoric acid to make nonhydratable phospholipids transform into hydratable phospholipids, at the same time, complex plenty of iron ions dissolving in oil in the high FFA production process,add little lye to make them neutralize and generate soap-stock and absorb impurities in oil,add hot water for water washing,discharge and recycle soap-stock,then temporarily store soap-stock in temporary storage tank.

1 ,Refining pot

Twospeed motor, the pot is heated using a serpentine coil, internal wing agitator, oil heating up fast, uniform washing, the use of automatic welding technology, looks good and beautiful.

Continuous drying and bleaching section

Use steam to heat oil after water washing,and pump it into continuous drying tower,through high vacuum to remove moisture in oil,then draw dry oil from the bottom into temporary storage tank before bleaching.

Add efficient active bleaching clay into oil,under vacuum condition, mix well and heat, make pigment solid tiny particles which suspends in oil absorb on the bleaching clay crystal particles, use leaf filter to remove them. The layout of this system is perfect,performance is reliable, high configuration of key equipments --- bleaching tower and leaf filter ensures high quality bleaching and separation for oil.

This technology has the following advantages:

1.Bleaching clay and oil mix under vacuum state when bleaching,avoid the effect from air,increase bleaching clay utilization efficiency, with better bleaching effect, at the same bleaching effect,bleaching clay consumption is smaller.

2.According to bleaching requirement, precisely and automatically meter bleaching clay addition percentage.

3.Continuous perfect mixture process makes all bleaching clay particles contact oil uniformly .

4.Temporary storage tank of decolorized oil adopts negative pressure design,effectively avoid oil contacting air, make the quality of intermediate product and final product be more stable.

5.Filtration of decolorized oil works in sealed filter with stainless steel filter leafs,residual oil rate of filter cake is low, operation is simple and convenient, equipment failure is low.

2, Drying, bleaching pot

Pot can double serpentine coil heating, cooling, under the head cone, automatic welding technology, looks good appearance, good airtight inner wing agitator and save energy.

Continuous deacidification and deodorization section

Soft tower deodorization technology represents the latest deodorization technology, it solves remaining issues in edible oil industry for years. Its technical process flow: Qualified decolorized oil is recovered most heat through efficient heat exchanger,then use heat conduction oil or high pressure steam to heat oil up to required technical temperature, and enters Deodorization Tower; deodorization tower is combined, upper layer is structure fillers,mainly used to remove FFA and other odor component,lower layer is board type structure,mainly plays hot bleaching role,and make product quality be more stable.Oil from deodorization tower is stored after series of heat exchanging and cooling.Volatile matters such as fatty acid out from deodorization,catch through packing catcher and become by-product.

3,High temperature deordorization pot

Deordorization pot using our three generations of energy-saving products, the overall automatic welding technology, the internal pressure steam injection system, ensure oil stir, high deodorizing efficiency, the internal double serpentine coil, heating, cooling quickly, saving energy.

Soft tower deodorization technology has the following features:

1.Technology is advanced and reliable,it’s widely adopted by big oil plants,and gain better effect.

2.Energy consumption is low, product quality is good, adopting combined deodorization tower and optimized heat exchanging system design,gave effective guarantee.

3.Deacidification ability is very strong,it can decrease the acid value of qualified oil ready for deodorization from 10mgKOH/g to 0.2mgKOH/g in short time.

6.4.5 Continuous winterization dewaxing section

Dewaxing is an important step to improve edible oil quality.Existing of wax mainly affect palatability of oil, therefore, the main purpose of dewaxing is improving palatability of oil,and its sensuality such as transparency and brightness.Different wax content for different oil,dewaxing is nearly necessary for corn oil,rice bran oil,sunflower oil and linseed oil,etc.This technology adopts counterflow type continuous process method, make oil crystallize thoroughly, use special filtration oil pump when filtering, shear force is small,filtration effect is good,wax and oil separate thoroughly, later adopts twice polishing filtration, further improve oil transparency.

Using energy efficient low shelf soda injection pump, pumping capacity, high efficiency, saving steam and other features.

Technical Highlights :

1,continuous mechanization to reduce human labor, reducing labor costs.

2, bleaching, deodorization part is closed operation, fully automated welding equipment package, look beautiful and clean.

Why Choose Us

1.Our factory is located in Huaxian County, the birth place of oil machinery in China, our factory covers an area of 100000m2, with 8 standard processing workshops, 202 sets of machining equipment, 580 staff, 12 intallation teams.

2.Our trademark "Hangpeng" win TOP 10 oil machine brand, because of excellent product quality and perfect after-sale service.

3.We have successfully obtained 27 national patents (including 8 invention patents), 6 international awards, 4 national awards and 2 provincial awards.

4.We have the most complete production certificates of oil machines, such as "Design license of pressure vessel","Manufacture license of pressure vessel","Design license of pressure pipeline","Installation,reconstruction and maintenance license of pressure pipeline", "Manufacture license of organic heat carrier furnace" and installation certification of mechanical and electrical equipment".

4. We are outstanding member enterprise of CCOA (Chinese Cereals and Oils Association), so we produce machines according to standard, and refined oil reaches the best edible oil standard.

5.We have strong R & D team, production team and installation team, offer perfect after-sale service, after delivering goods, we will dispatch technicians to instruct installation, commissioning and train your workers to operate machines by yourselves.

6.We are provincial enterprise abiding by contracts and keeping promises, we have produced oil machines for 65 years, with rich experience and own brand, so we are responsible for all of our projects, especially for oversea projects.

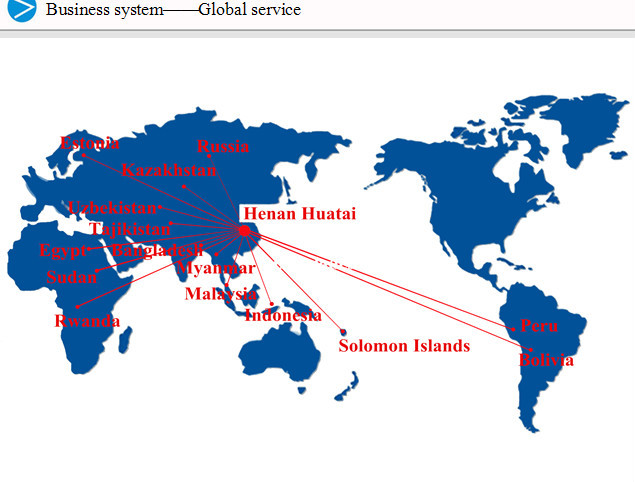

7.Overseas projects: we are establishing every perfect overseas sample project all over the world, such as Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia, Bangladesh, Thailand, the Philippines, Myanmar, Egypt, Sudan, Nigeria, Rwanda, Tanzania, etc.

Contact us if you need more details on Vegetable Oil Refining Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Corn Oil Refining Machine、Oil Refining Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Oil Machine > Sunflower Oil Machine

Premium Related Products