Rapeseed Oil Extraction Machinery

Basic Info

Model No.: HT-280/350/450

Product Description

Rapeseed Oil Extraction Machinery

Extractor type: Rotocel extractor, loop extractor, chain extractor.

Specification: 20-5000T/D

Suitable materials:Flakes,expanded materials or pressing cake from prepressing plant.

1.Working principle of rapeseed oil extraction machinery:

Oil extraction process is a kind of making oil method utilizing the character that oil in oilseeds dissolves in selected solvent and diffuse together.It is a mass transfer process,also used in chemical operation.Evaporate and strip mixture of oil and solvent according to different boiling points between volatile solvent and non-volatile oil, make solvent vaporization into gas and separate from oil to get crude extracted oil.Solvent can be recycled after condensation.There is some solvent in meal,it needs drying to recover and get dry meal.

2. Extraction Process of rapeseed oil extraction machinery:

Soybean flakes, expanded rice bran pellets or pressing cake from prepressing plant is conveyed to extractor through feed hopper with material level controller,and moves into curved section together with chain, spray it with miscella with diminishing concentration in moving process, miscella falls down into miscella collection hopper through the gap of grid tray, then pump it out and spray pressing cake again and fall down into the second miscella collection hopper,pump the miscella out into cyclone hydraulic separator through concentrated miscella pump to remove powder impurities and then enters evaporation system. Before materials enter draining section, spray it with fresh solvent again,drained wet meal discharges from the outlet of meal and enters wet met scraper Conveyor.

2.1There are twice reversal in the whole extraction process,it’s beneficial for the uniformity of solvent and miscella to material layer; low material layer extraction is beneficial for quick permeation and draining of solvent and miscella,shorten extraction time;reduce residual solvent rate and residual oil rate in meal, loop extractor is dismountable, convenient for transportation;feeding material and discharging meal are uniform and continuous, beneficial for pressure stabilization of the whole system,with advantages of low power consumption, stable operation, no noise, low maintenance cost.

2.2 Feeding system has material level controller according to feeding capacity, make feed hopper keep certain material level all the time,beneficial for forming micro negative pressure in extractor, reduce solvent leakage.

2.3 Advanced miscella circulation theory design is beneficial for reducing input of fresh solvent, reducing residual oil in meal, improving miscella concentration, achieve energy-saving purpose through reducing evaporation capacity.

2.4 Especially suitable for all kinds of prepressing cake extraction.

3. Desolventizing-toasting Process

Wet meal with solvent out from extractor is conveyed to preliminary desolventizing layer of DTDC,integrating desolventizer,toaster,dryer and cooler, with wet meal scraper conveyor via airlock, the bottom uses indirect steam to heat, remove part of solvent; wet meal after preliminary desolventizing enters toasting layer,which sets automatic control to keep certain material layer, steam from the bottom to remove all solvent, at the same time, part of steam congeals in meal,the moisture of meal will increase partly. Desolventized meal material level is controlled by each layer, drying layer keeps certain material level, to dehydration and drying process.Finally control discharging materials with automatic material door, then use meal scraper conveyor to convey meal into meal warehouse.

Mixed vapor of solvent out from the top of desolventizer-toaster and water vapor, goes through solvent catcher ,then enters condenser for cooling recovery.

3.1 Unique breathable pan design,beneficial for good contact between materials and steam,with good desolventizing effect,small direct steam consumption,low outlet temperature of twice steam.

3.2 Preliminary desolventizing layer and permeable layer adopt horn mouth discharging materials, with good sealing, uniform discharging materials, stable material layer, adopt automatic material door discharging controlled by this layer.

3.3 Meal quality is stable,urease activity reaches national standard,color is light yellow and uniform,no clustering phenomenon,moisture is adjustable,temperature is a little higher than room temperature;

3.4 Reducers of main machines adopt famous brand product, performance is stable,failure rate is low.

4. Evaporation Process

Miscella enters the first long tube evaporator tube pass from miscella tank, evaporated solvent enters evaporation condenser through separation chamber,outlet pipelines of separation chamber set liquid level control device to keep liquid seal. Miscella enters disc of tower from the top of steam-stripping tower,fall layer by layer,at the same time inject direct steam from the bottom,remove residual solvent.Top outlet connects evaporation condenser, use high vacuum injection pump to keep steam-stripping tower work under negative pressure,equipped with liquid level controller on the bottom of steam-stripping tower to ensure liquid level and stable flow of finished oil,crude oil is drawn from tower bottom with steam-stripping drawn pump to cool and then enters crude oil tank.

4.1 Evaporation temperature is low, residual solvent in crude oil is low, color is light,no phospholipids precipitation,evaporator and steam-stripping tower scaling not easy;

4.2The advantages of using long tube condenser is high solvent recovery rate,reducing condenser area and saving investment cost.

4.3 Using boiling tank makes solvent in drained waste water reach the minimum value.

5. Solvent condensation and water separation process

Condensate from extraction condenser,desolventizing condenser, evaporation condenser and steam stripping condenser gathers and recycle through condensate into water separation tank.Free gas in solvent warehouse gathers and enters final condenser, uncoagulate gas out from final condenser enters new type energy-saving water bath exhaust gas recovery device. Solvent in water separator flows into solvent warehouse for recycling, water is drained into boiling tank, steam from the bottom of boiling tank to evaporate residual solvent then drain to water seal tank.

6. Extraction Process Advantages of rapeseed oil extraction machinery:

6.1 Adopt purification processing for miscella, concentrated miscella enters one-stage cyclone hydraulic separator to remove meal powder.There is hardly solid impurities in miscella after cyclone hydraulic separation, clean miscella is pumped to miscella temporary storage tank for further precipitation. Sediment on the bottom of miscella tank is pumped to extractor with oil residue pump regularly. Application of negative pressure evaporation process of miscella, reduces scaling of evaporation system greatly.

6.2 Adopt negative pressure technology,solvent and vapor out from DTDC enters No.1 evaporator,as heat source of No.1 evaporator, save energy,reduce energy consumption.

6.3 Twice steam in condensate tank is used to preheat waste water,reduce steam consumption.

6.4 Collect all waste water in extraction workshop,and pump it into boiler room for reutilization, utilize waste heat of used water,save production water supply

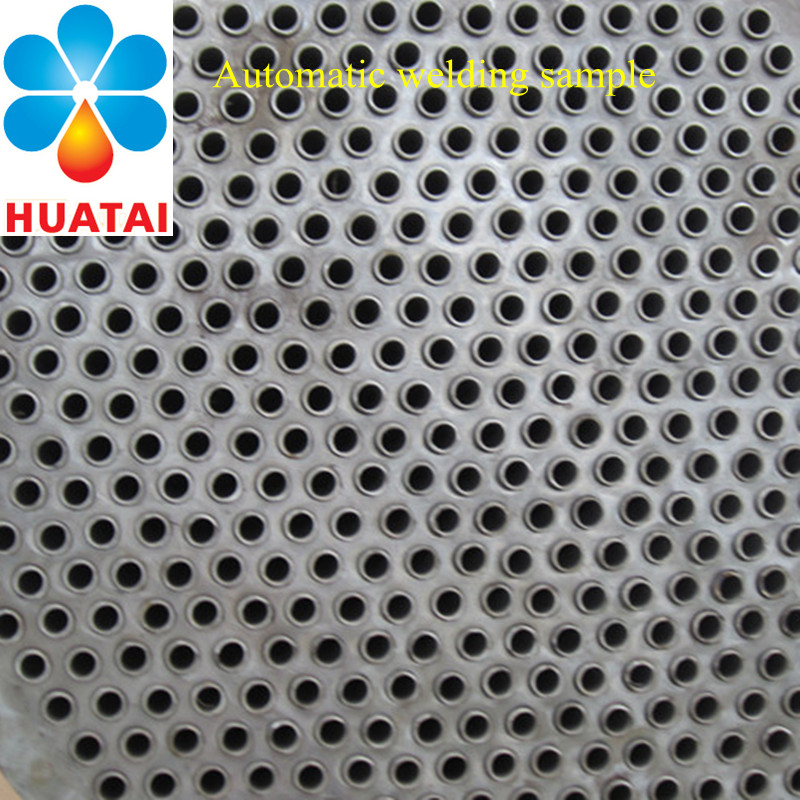

We have 210 senior engineering technicians among 580 staff, invest USD60,000.000 to establish 8 production workshops, 2 machining workshops,with 202 sets of automatic processing equipment, such as automatic laser cutting machine, flame cutting machine, double housing planer,union melt welding machine, tube-sheet welding machine, etc, annual processing capacity is more than 3000 sets.

Henan Huatai Cereals and Oils Machinery Co., Ltd. ,outstanding membership enterprise of CCOA,also public company in Oil Machine field in China.We are a large scale oil machinery manufacturer integrating research, development, design, manufacture and installation.We have self-supported import and export right and has passed ISO9001:2008 Quality Management System Certification.Registered trademarks"Huatai" and "Hangpeng" won Henan provincial famous brand,and was awarded "Provincial outstanding quality products".

We have successfully obtained 29 national patents (including 9 invention patents), 6 international awards, 2 national awards and 2 provincial awards. Our oil machines sell well in more than 30 provinces, cities and districts, and exported to Estonia, Russia, Kazakhstan,Uzbekistan,Tajikistan,Malaysia, Indonesia, Egypt, Bangladesh, Myanmar, the Philippines,Nigeria, Sudan, Tanzania,Rwanda,Bolivia,Peru and other countries, and now we have developed into a major oil machinery manufacturing base in China.

Packing: Our oil machines adopt wooden case or power distribution cabinet and motors, reducers, and adopt solid packing for flanges, meters, valves,etc.

For all machines, after sand blasting and rust protection, also use film to keep cleaning before delivery, also fixing treatment to prevent rolling and collision.

Delivery: We have gantry cranes in every workshop for heavy machines, and forklifts for normal machines.

Contact us if you need more details on Oil Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oil Extraction Machinery、Rapeseed Oil Extraction Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Oil Extractor

Premium Related Products