price list of animal fat melt oil and refining facilities, animal fat oil machine, animal oil refinery plant

Basic Info

Model No.: 6YL-120

Product Description

animal fat melt and crude oil refinery plant, animal fat melt oil and refining facilities, animal fat Oil Machine, animal oil refinery plant.

Full continuous animal oil melt and refining plant is the patent product of Henan Huatai,

according to the needs of people, small batch-type processing equipment has been not satisfy the needs of the society.

Our research and development team , after the process design, equipment manufacture, test machine, normal operation of equipment, successfully designed a set of China's first full continuous animal oil melt and refining equipment.

The machine processing technology : Continuous feed, then come into continuous animal oil melt system after continuous ground meat machine, meat fat melt by high temperature heat conduction oil heating.

Transmission equipment in internal are turning, otherwise there is continuous dregs system, the residue can be processed by Oil Press.

Full set of facilities for closed mode, simple operation, easy maintenance, economizes manpower, and protect the safety of operator, adopting the button in the electrical cabinet process control system.

Why is Vegetable Oil Refined?

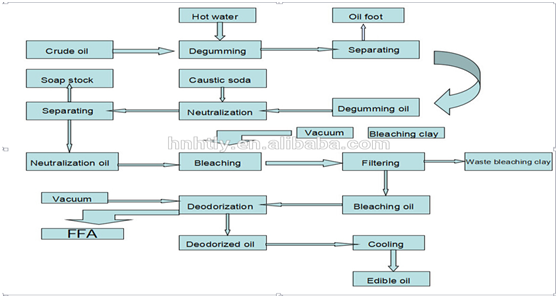

Vegetable and Animal Oils and Fats have impurities such as Moisture, Solids (Insolubles), Gums (Lecithins), Free-Fatty Acids (FFA), Waxes, and Compounds of Sodium, Potassium, Magnesium, Calcium, and other metals. These impurities must be removed to improve the functionality of the oils. Other characteristics of oils (such as Color, odor, and taste) are also considered impurities by modern consumers. These impurities are removed in a series of steps such as degumming (to remove gums), neutralizing (to remove FFA), bleaching (to remove color), deodorizing (to remove odor and taste), and dewaxing or winterization (to remove waxes).

The draft of crude oil refinery equipment list

(1)continuous alkali refining shortens contact tome between oil and lye,which reduces oil saponification state,lowers refining consumption,and improves efficiency;

(2)decolorization craft adopts technology of combining premixing and steam mixing bleaching,which improves bleaching efficiency,saves consumption of bleaching clay, and it is simple and convenient to operate ; besides,negative pressure state avoids oxygen in the air from contacting with hot oil,thereby ensuring oil product quality ,inhibiting with hot oil,thereby ensuring oil product quality,inhibiting acid value to rise again,and lowering peroxide value;

(3)physical refining section adopts new type continuous deacidiffication and deodorization craft,which is applicable for vegetable oil of high acid value and low resin content,the actual production proves its most obvious advantages as following: strong deacidiffication ability ,excellent hot bleaching effect,high refining rate ,good oil quality etc.

Alkali-refining desoap system

Decolorization system

Leaching system

Freezing filtration system

Vacuum system

Product quality index of Oil Refinery Equipment List :

transparency | clear and transparent |

gas taste | No smell |

color ( lovibond colorimeter 133.4 slots) | less than R1Y10 |

moisture and volatile matter | less than 0.10% |

acid value (mgKOH/g) | less than 0.2 |

Peroxide value (mep/kg) | less than 5 |

Henan Huatai Cereals And Oils Machinery Co., Ltd. (short for HHFOME) is a manufacturing enterprise specialized in producing oil and cereal processing equipments in China. HHFOME consists of Henan Huaxian Grain Machine Factory, Huaxian Hangpeng Grain Machinery Co., Ltd. and Beijing Huakang Xiwang Biological Technology Co., Ltd. Established in 1988, HHFOME covers an area of 100,000 square meters and has 210 senior engineering technicians. Our company has 202 sets of automatic processing equipment. Processing capacity of our enterprise is more than 3000 sets every year. HHFOME has obtained independent export rights and has passed the evaluation of ISO9001:2000 Quality System Management Certification. We have obtained 27 national patents (including 7 invention patents), 5 international awards, 4 national awards and 2 provincial awards.

1.Do you supply engineers to install the machine and train our workers ?

Sure, we are the manufacturer, we supply turn-key project line for our customer.

Our engineer will give your workers free training .

2.Do you supply after sales service and how you guarantee you have the ability and the quality ?

We are big company .we are manufacturer , not trade company . we have our own bran "Huatai "and over 27 patents . we offer one year guarantee time for your machine .we are member unit of China Oil Associattion . Also we can let the third party as the guarantee .

Looing forward for your enquiry! Welcome to our factory!!!

Contact us if you need more details on Animal Oil Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oil Refining Machine、Animal Oil Refinery Plant. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Linseed Oil Press Machine

Premium Related Products