2016 Polular Corn Grinding Machine to Make Corn Flour

Basic Info

Model No.: HT--CDPM

Product Description

Corn Deep Processing Machinery

The processing of corn flour adopts combined dehusking and degerming technology,and it can produce different granularity of low-fat corn grits,corn flour and corn bran.Corn grits and corn flour are suitabe for foodstuffs factories,alcohol plants,wine plants,breweries,lactic acid factories,corn sugar mills and other processing enterprises using corn as material.They are also ideal foodstuffs for urban residents to have better life.Corn bran can be used for feeds(It can be directly packed without drying).

Specification: 5~2000T/D

Grain transporting----- cleaning-----conditioning----- flouring----- sieving-----packing.

Series of corn flour mill machinery:

1. Equipment technical parameters:

1).Product variety: corn grit, corn flour and corn bran.

2).Electricity consumption: about 60kw·h for one ton of corn

3).Rate of finished product: corn grit: about 45~55%; corn flour: about 20~30%; corn bran: about 25%.The total rate of corn grits and corn flour is about 75~80%.

2. Finished Product Indexes:

1).Fineness of corn flour: 40~150 meshes (Adjustable)

2).Sand content: ≤ 0.002%

3).Magnetic metals content: ≤ 0.003g/kg

4).Moisture: storage type: 13.5~14.5%

5).Color and scent: pink, normal odor and taste

6).Fat content : 0.5~1%.

3. Total power of equipment: 105kw

4. Occupied area of equipment: 10m(L)*5m(W)*5.5m(H)

Notes:

1.After you process corn into corn grits and corn flour, corm germ can be also utilized to produce corm germ oil.Pls contact us for more details.

2.we have different capacity maize flour milling plant,wheat flour milling line,we can according to the customer need,equip the different capacity flour milling line.

3.The plant consists of five main parts namely cleaning part, peeling & degerminating part, grits milling part, flour grinding part and packaging part.

Our Company

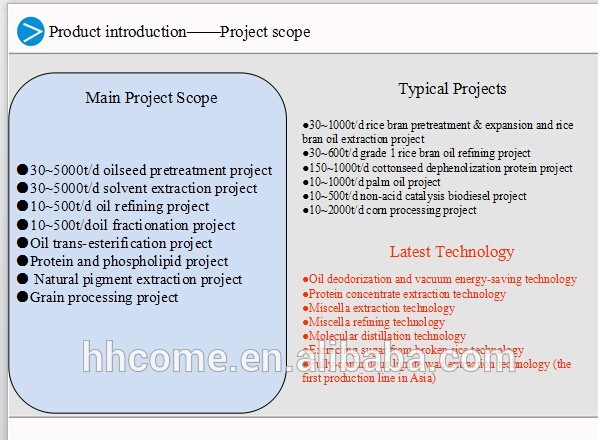

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters.

Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, Oil Extraction, oil refining and oil fractionation production line project,Conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology, and Palm Oil Processing lines,etc.

Our company always put the interests of customers and product quality to the first place, and always adhere to the"no best, only better" as our purpose. We will be commitment to provide high quality products with perfect site services and after-sales service. Now the specific commitments are as follows:

field installation debugging.

8. After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, online debugging and Feeding trial operation,to ensure that equipments can normal operate in full load conditions. We will provide all kinds of information and records according to the requirements of the bid.The qualified completion files will be provided to customers according to their requirements within one month after acceptance.

9. In the warranty period, all because of the quality of products has caused the damage or failure of

equipment,suppliers will take the responsibility for the free repair and replacing spare part.

Due to the damage caused by the customer,we only charge material costs for repair and replacement. After the receipt of customers notice,we will suggests the method to solve problem within six hours,or send specialist to the site to solve the problem within twenty four hours.

Contact us

Product Categories : Feed Processing Machine

Premium Related Products