Factory Sale Vertical Grain Bucket Elevator

Basic Info

Model No.: TDTG

Product Description

TDTG Self Clean-up type Bucket Elevator features:

Product Features:

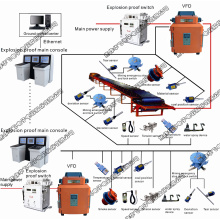

1.It is used for vertical transportation of oilseed ,and the structure is compact.

2.It is set with the joint body base,thereby the power machine,the machine head and riser can be effectively connected with the joint body base,

3.The head pulley adopts the rubber covering process,thereby increasing the friction coefficient and transmission efficiency.

| Item/Model | TDTG31/13 | TDTG36/18 | TDTG40/23 | TDTG50/28 | TDTG60/31 | TDTG60/34 |

| Conveying Capacity (m³/h) | 12-25 | 20-30 | 30-45 | 50-70 | 60-120 | 80-160 |

| Hopper Wide(mm) | 134 | 180 | 235 | 282 | 315 | 337 |

| Hopper Volume(L) | 0.75 | 1.7 | 3.0 | 3.7 | 5.1 | 3.5 |

| Hopper Space(mm) | 125 | 170 | 190 | 225 | 240 | 200 |

| Hopper Speed(m/s) | 2.14 | 2.28 | 2.4 | 3.18 | 3.18 | 3.18 |

| Traction Belt width(mm) | 150 | 212 | 250 | 315 | 350 | 350 |

| Head pully diameter(mm) | 315 | 355 | 400 | 500 | 600 | 600 |

Henan Huatai Food & Oil Machinery Engineering Co., Ltd, - International Leading Manufacturing Expert of Grain and Oil Machines

Founded in 1953, Henan Huatai Food & Oil Machinery Engineering Co., Ltd. Is a large-scale and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit Oil Machine, vegetable Oil Pretreatment, prepress, extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.

Main Projects Scope:

-----30-5000T/D oilseeds pretreatment project

-----30-5000T/D oilseeds extraction project

-----10-500T/D crude oil refining project

-----10-500T/D crude oil fractionation project

-----Oil interesterification project

-----Oilseeds protein, phospholipids project

-----Natural pigment extraction project

-----Grain deep processing project

Typical Project:

----30-1000T/D rice bran pretreatment, expanding, extraction project

----30-600T/D rice bran oil refining project

----150-1000T/D cottonseed dephenolizing protein

----10-1000T/D palm fruit oil pressing project

----10-500T/D Non acid method biodiesel production project

----10-2000T/D corn deep processing project

Newest Technology:

---Energy saving oil vacuum deodorization technology

---Concentrated protein extraction technology

---Mixed Oil Extraction technology

---Mixed oil refining technology

---Molecular distillation technology

---Broken rice desaccharification technology

---Continuous lignite extraction technology

Service Police and Technical Support

Generally, we guarantee all equipments are completely new and unused, and under normal operation conditions the warranty period would be 12 months after installation or 18 months from the date of shipments whichever comes first.

Our equipment would be shipped in containers. Equipments too large for containerized shipment would be covered and protected from sea water damage.

We can send experienced and qualified engineers (electrical engineer and mechanical engineer) to the Buyer's site for supervision of equipment installation and commissioning. And after the plant had been successfully commissioned, our engineer will stay to train the buyer's plant personnel in process operations and equipment maintenance by buyer's request.

If u have any questions, please just email me or call me.

Product Categories : Single Equipment > Conveyor

Premium Related Products